Optimized solutions for Raw Material, finished product handling systems, Packaging Workstations, Warehouse Automation.

In-Plant Logistics covers the range of Logistics activities carried out for Raw Material/additives storage, movement withn plant and finished product movement and storage.

The activities that form In-Plant logistics are –

Raw Material Storage and handling. Supply of Raw Material to Production Line. Finished Products – Move from Production Line to planned storage/Warehouse. Finished product warehousing and dispatches. Movement of In-Plant circulation containers, handling boxes (e.g. returnable pallets, bobbins in textile industry), Movement of packing materials, re-usable scrap.

We provide –

Optimized Handling Systems for raw material, which will be synchronized with production rate and will move materials with zero handling loss, optimum handling cost and incorporate features of inventory management. Optimize Raw Material Unloading and Finished Product dispatch operations. This prominently includes “Optimum container stuffing”. Packaging Work Station : Automation of Packaging Work Station is the most important part of our services in In-Plant logistics. Packaging Automation:

Packaging Automation is the most important feature of In-Plant Logistics. We design Automated Packaging Work Stations, which incorporate following features

Zero Material Loss Optimum Packing rate Incorporate possible features like-Bag feeding Auto-Stitching Auto-Taping, Strapping, Labels printing & application. Palletization Linking Packaging with Warehouse Management System. Close control on Material weight. Decide optimum location of Packaging Work station from Production Line to Warehouse.

The Packaging work stations are designed, selecting the above features with objective of optimum packaging cost. We include packaging of powders, liquids, unit weights (example : Yarn Packages)in our services.

Warehouse Automation :

At Adishree Tech Solutions, we strive to work on Warehouse to transform them into “Profit Centres” from cost avenues. We firmly believe, a well-designed Automated Warehouse is THE BEST advertisement of the Organization, it’s product and projects the business in high esteem. We follow the standard Industrial Engineering method in Warehouse design.

Warehouse Design:

- Find out stock requirement of product, based on types of customers, season-wise variation, product shelf life, etc.

- Define SKU to bring the products of all types under one common storage Unit.

- Compute and summarize SKU required for warehousing.

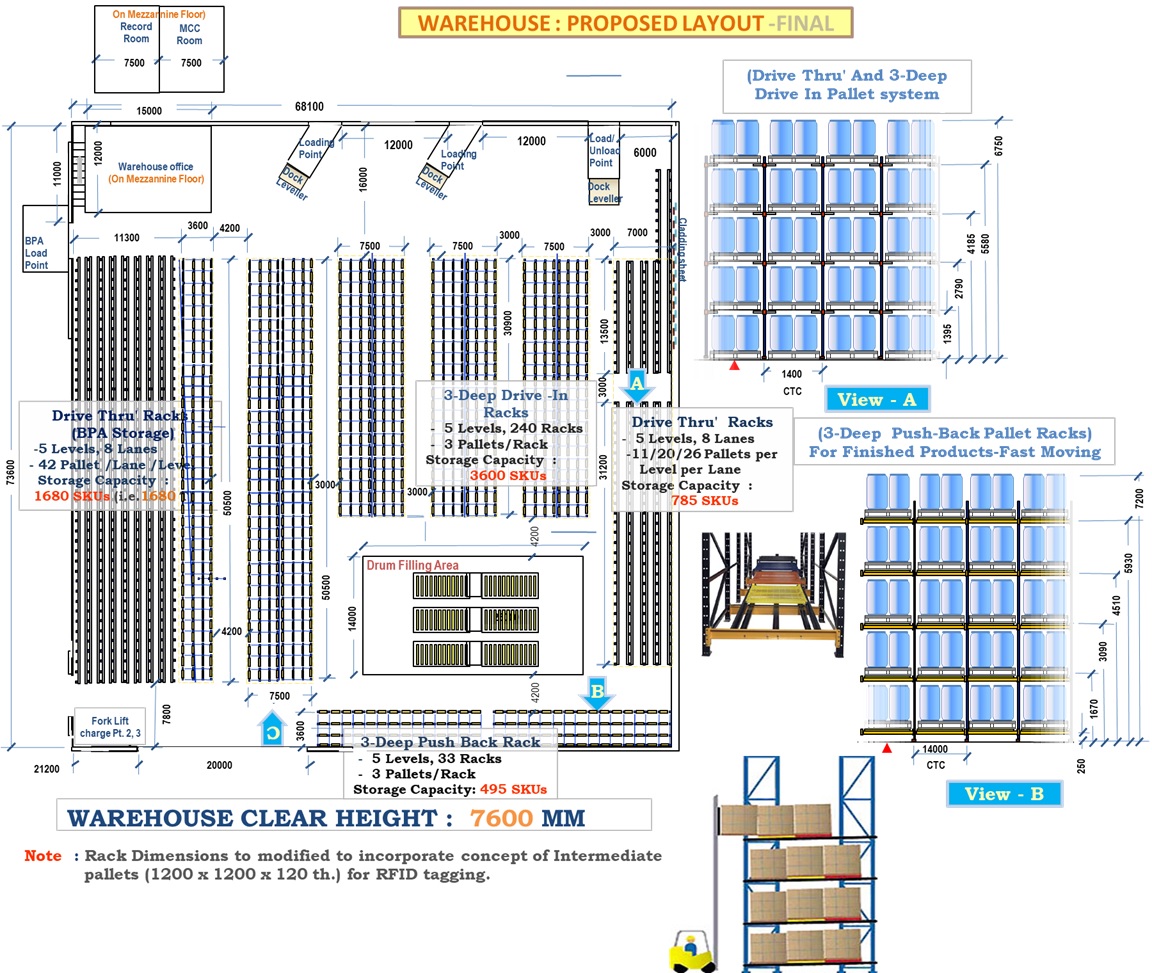

Design overall Warehouse Layout based on –

- Possibility of introducing the concept of “Rack Supported Roof Structure”.

- Cubic Space Utilization.

- Dispatch points required, calculated on the basis of dispatch rate.

- Incorporate features of Warehouse Automation, like-

ASRS Drive-In/Drive Thru’ Racking Dynamic Rollers Pallet Runners Vertical Carousels, Moveable Rack Systems Deep Push back racks. (Decided by applicability to product & warehousing).Incorporate the suitable storage concepts (from above) in the Warehouse to form optimum product storage and flow proposition. Select Material Handling Equipment(Pallet Stackers, Forklift trucks, Conveying Systems, etc.) compatible for proposed Warehouse. The effectiveness of Warehouse design is measured in terms of-

- Ratio of Aisle & Operating area to Total Warehouse area.

- Storage Capacity created (say, T/M3).

With proven experience in dealing with situations in In-Plant Logistics, we provide services to all kinds of businesses (retails, process plants, textiles, Automotive and Engineering Industry).